Let’s Create Your Perfect building

Request a quote or begin designing your own building!

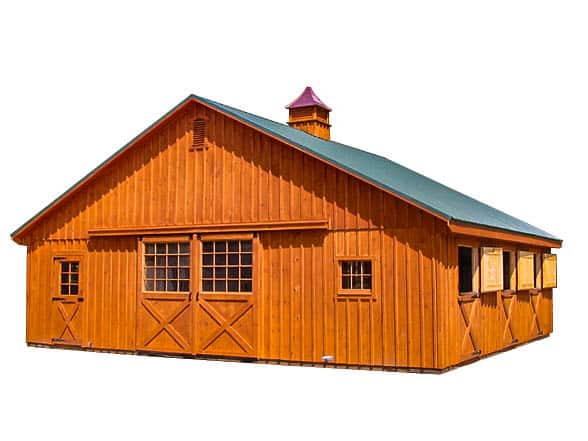

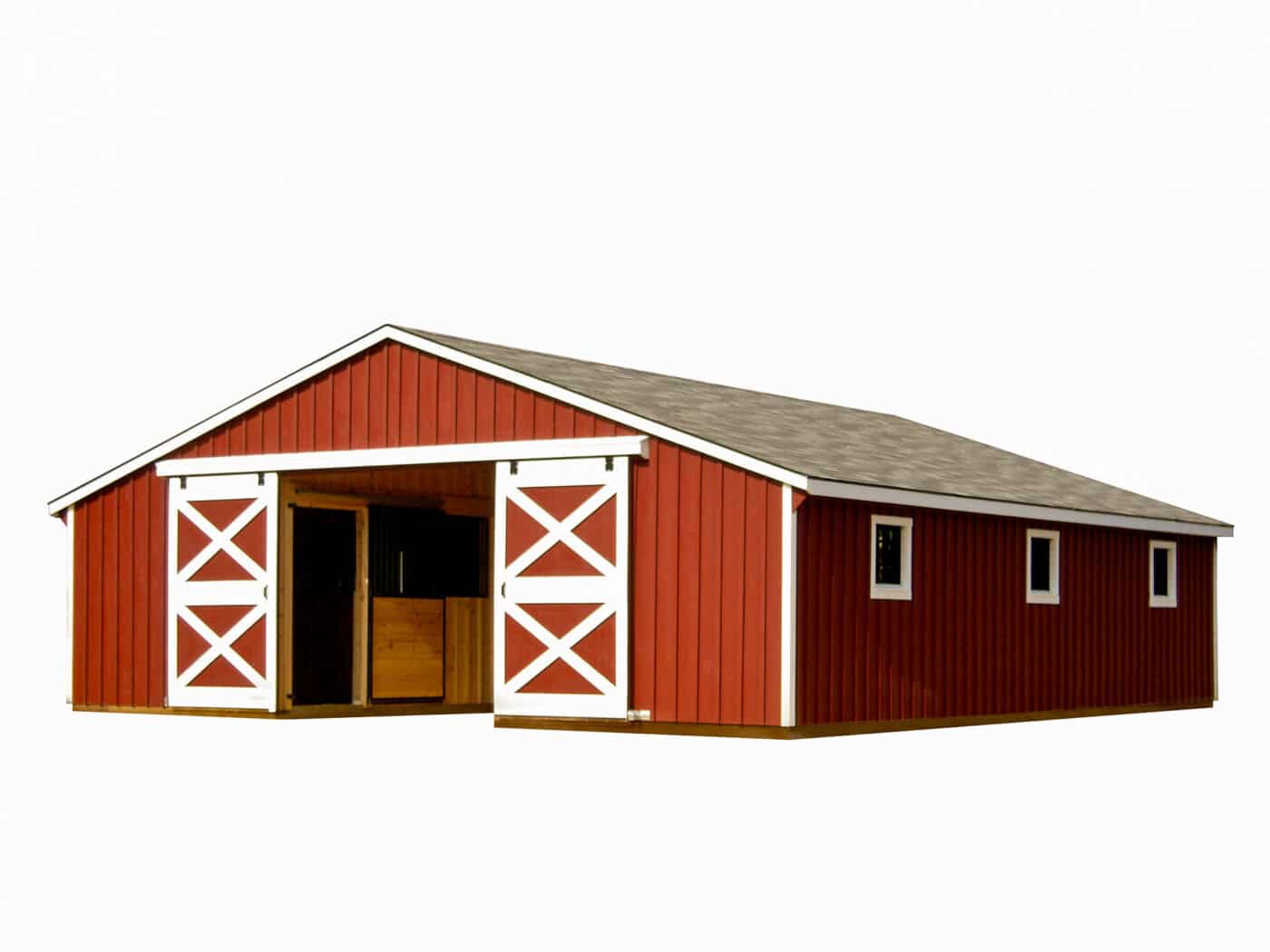

Whether you need a cost-effective storage space, a spacious workshop, or even a modern living space, pole barn framing provides a durable and versatile building solution. Thanks to its affordability, quick construction, and flexible design, pole barn framing is becoming an increasingly popular choice for residential, agricultural, and commercial projects.

At Premier Building Solutions, we specialize in high-quality pole barn framing and crafting structures tailored to your exact needs. But is pole barn framing the right fit for your project? In this blog, we’ll break down what pole barn framing is, how it’s built, and its key advantages and considerations—helping you make an informed decision before getting started.

Pole barn framing is a building method that skips the traditional basement or full foundation. Instead, it uses deep-set posts anchored into the ground with concrete, creating a strong and flexible structure. That’s why it’s a go-to choice for everything from farm storage and livestock shelters to garages, workshops, commercial spaces, and even modern barndominiums.

Pole barn posts, typically made of pressure-treated wood or steel, serve as the primary vertical support for the structure. They are buried into the ground and set with concrete. Typical post sizes are anywhere from 4×4 to 8×8 in size.

Trusses are usually made of wood or metal and provide roof support and distribute weight evenly across the structure. They typically span the width of the pole barn and support the roofing materials

Girts, or wall framing, are horizontal supports for the exterior walls and add structural stability. These supports are usually made of wood or metal and are fastened to the posts as a frame for siding installation. The most common girt sizes are 2×4, 2×6, and 2×8.

Pole barn fasteners are typically made of galvanized or corrosion-resistant steel to protect them from rust.

Purlins are horizontal beams that attach to the trusses to provide roof decking support and prevent sagging by distributing the load evenly. These components are typically 2×4, 2×6, and 2×8 in size.

The roofing protects the building from the elements and is most commonly made of metal panels. However, a roofing contractor can install asphalt shingles or other materials based on the design.

The siding covers the exterior walls and provides protection and visual appeal. Metal panels are the most common siding choice, but wood, vinyl, and other materials are also used.

Skirt Board, also known as Splash Board, is made from pressure-treated wooden board and protects the base of the structure from moisture, rot, and impact damage. It’s installed along the bottom of the wall framing, helping anchor the siding.

Concrete Footings, or Backfill, secures the posts in place and prevents shifting or sinking. The posts are either set in concrete or surrounded by compacted gravel for stability.

Doors and windows provide access, ventilation, and natural light. Options include sliding doors, roll-up garage doors, walk-in doors and windows depending on the barn’s purpose.

Insulation and vapor Barriers regulate temperature and moisture, improving energy efficiency. Spray foam, fiberglass batts, or rigid foam insulation can be installed along walls and roofs. A vapor barrier helps prevent condensation.

Interior liner panels, usually metal or plywood, provide a finished look to the interior of the pole barn and protect insulation. They help create a cleaner look and a more durable interior.

Pole barns can vary widely in size. Common dimensions include 30′ x 40′, 40′ x 60′, and 40′ x 40′. Building in increments of 8, 9, or 10 feet is typically more cost-effective due to standard post spacing.

The standard spacing between pole barn posts is 8 feet. However, depending on factors like building size and local conditions, this distance may vary between 6 to 10 feet.

If you’re planning a new building project, one of the first big decisions is choosing between pole barn framing and stick-built framing. At Premier Building Solutions, we specialize in high-quality pole barns that offer durability, affordability, and versatility for farms, businesses, and even homes. But how does pole barn construction compare to the traditional stick-built method? Let’s break it down.

Pole barns require fewer materials, resulting in lower material costs compared to traditional stick-frame buildings. Also, their faster and easier construction reduces labor expenses. And since pole barns don’t require a full basement or concrete foundation, overall costs are lower.

Pre-engineered components allow for a quick construction time. Fewer structural components also allow for a more efficient building process.

Open floor plans eliminate the need for load-bearing interior walls, which makes it great for various uses such as agriculture, storage, workshops, homes, and commercial buildings. Also, pole barns are easily expandable, making it possible to add extra space in the future.

The construction of pole barns is durable enough to withstand harsh weather conditions, including strong winds and heavy snow. Its deep-set posts provide structural flexibility, making it more resilient to shifting soil conditions.

Pole barns don’t typically allow for basements, unlike traditional stick-built buildings. Also, if a concrete floor is needed, it’s often installed after construction, adding to the overall costs.

Additional features like vapor barriers and drainage systems may be necessary to manage condensation. Lack of proper insulation and ventilation can lead to moisture buildup. Which can result in mold, rust, or wood rot.

Some local regulations may require additional engineering or modifications, particularly for residential or commercial pole barns. Permit requirements may vary with some locations needing specific foundation or wind-load adjustments to meet building codes.

At Premier Building Solutions, we can help navigate zoning regulations and ensure your pole barn meets all necessary codes.

Now that you know more about pole barn framing—how it’s built, its key components, and the versatility of different styles—you’re better equipped to decide if it’s the right choice for your project.

Need help with your pole barn frame? Premier Building Solutions is here to help you with a custom-built pole barn tailored to your needs. Contact us today to discuss your project and get a free consultation!